6KW household photovoltaic system in Cangzhou, Hebei Province, China

Ⅰ Design process

1. Project Introduction

Farmers build their own houses facing north and south, hoping to install photovoltaic power stations on the idle rooftops. ELINK TECHNOLOGY provides 300Wp modules, and after calculation, 22 modules can be installed on the rooftop area.

2. Component selection

The user hopes to have the largest installed capacity possible, so they have chosen the 300Wp high-efficiency component, which has excellent low radiation performance. Its technical parameters are as follows:

(1) Main parameters of the component

Pm=300Wp;

Voc=39.85V,

Vmpp=32.26V,

Imp=9.30A,

Isc=9.75A。

(2) Calculate the installed capacity of 6.6KWp (300Wp x 22 pieces) based on the model of the components and the number of installations. Select the appropriate inverter based on installed capacity and actual component layout.

3. Bracket scheme

This project is a sloping roof with glazed tiles. When installing the brackets, the main support components are generally fixed to the lower layer of the glazed tile roof to support the main beams and crossbeams of the brackets. Aluminum alloy pressure blocks are used to press the components and crossbeams together. During the installation process, it is essential to ensure proper waterproofing of the roof and arrange cables in a reasonable manner.

4. Selection of inverters

The project has a capacity of 6.6kWp and a grid connected voltage of 220V, so we chose the single-phase dual channel ELKTCFGD6248JMH photovoltaic inverter with an over ratio of 1.1 times.

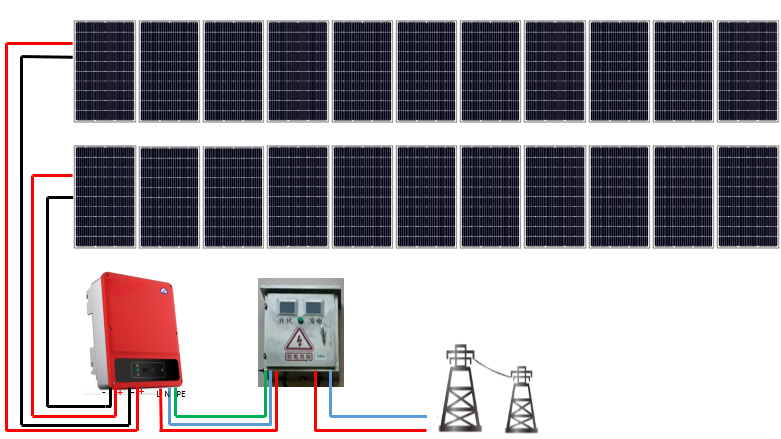

The orientation and inclination of the components are completely consistent, divided into two identical strings, each string consisting of 11 components, connected to the DC side of the inverter. As shown in the following figure.

5. Cable selection

(1) DC side cable

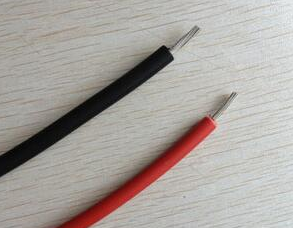

DC cables are mostly laid outdoors and require moisture resistance, sun protection, cold resistance, UV protection, etc. Therefore, DC cables in distributed photovoltaic systems are generally selected as photovoltaic certified special cables. Considering the DC connectors and output current of photovoltaic modules, the commonly used photovoltaic DC cables are PV1-F 1 * 4mm ².

(2) Communication side cable

AC cables are mainly used from the AC side of inverters to AC combiner boxes or AC grid connected cabinets, and YJV type cables can be selected. For long-distance installation, voltage loss and current carrying capacity should also be considered. It is recommended to use YJV-3 * 6mm ² for 6KW single camera AC cables.

Note: AC/DC cables are generally installed outdoors and are usually protected by PVC pipes.

6. Selection of distribution box

Internal component description:

(1) Circuit breaker

One end of the circuit breaker is connected to the inverter, and the other end is connected to the grid side; AC circuit breakers are generally selected to be at least 1.25 times the maximum AC output current of the inverter. For a 6kW inverter, the maximum AC output current is 27.3A, which means at least 40A circuit breakers should be selected.

(2)Fuse

When the surge protector is broken down by lightning, causing a short-circuit fault in the circuit, in order to cut off the short-circuit current, a set of fuses needs to be added to the surge protector. The selection of fuses is the same as that of circuit breakers, with a specification of 40A. If the fuse burns out, it should be replaced in a timely manner and can be replaced by a circuit breaker. The circuit breaker has instantaneous current protection function and can be manually reset after tripping without the need to replace components.

(3) Surge protector

This project uses voltage limiting SPD, 2P surge protector, with specifications Uc~385V, Imax ≥ 20KA, In: ≥ 10KA, Up ≤ 1.5KV.

(4) Self resetting overvoltage and undervoltage protector

The overvoltage and undervoltage protector can automatically detect the line voltage, and can automatically disconnect when the overvoltage and undervoltage in the line exceed the specified values. The specifications of the self resetting overvoltage and undervoltage protector used in this project are working voltage AC 220V 50HZ, rated current 40A, overvoltage value AC270 ± 5V, undervoltage value AC170 ± 5V, protection action time ≤ 1s, and delayed connection time ≤ 1min.

(5) Knife switch (isolation switch)

Knife switches or isolation switches will have obvious disconnection points, which can ensure the safety of back-end maintenance and repair personnel. Select a knife switch with a rated current of 63A.

(6) Grounding measures

The grounding wire is the key to the normal operation of the photovoltaic system. In areas with thick and humid soil layers near the house, a 1.5m deep pit should be excavated according to the requirements of the power supply company. A 50 * 5mm flat steel or a φ 12 round steel should be buried, and a resistance reducing agent should be added and the grounding wire should be led out. The grounding wire should be connected to the bracket of the component, and the component frame must also be connected to the bracket. The grounding resistance should be less than 4 Ω.

Ⅱ Design scheme diagram and checklist

1 Design proposal

2 Material List

Ⅲ Profit calculation

1 Estimation of power generation

The installed capacity is 6.6kW, PR=80%, and the estimated annual power generation is 1200 hours (in Shandong region). The first year's power generation is 6336kWh. The attenuation in the first year is 2.5%, and the lowest power at the end of the 25th year is 80%.

Note: The cumulative power generation in 10 years is 60000 kWh, and the cumulative power generation in 25 years exceeds 140000 kWh.

2 Actual power generation

According to the GPRS monitoring in Cangzhou City, Hebei Province, the maximum grid connected power of the 6kW inverter is 5.5kW, with a cumulative daily power generation of 32.2 kWh. The local weather is very good and the power generation is normal.

conclusion

This project has designed a photovoltaic power station with the premise of maximizing the installed capacity, including the selection of relevant equipment, overall design scheme, material list, and revenue calculation of power generation. It has provided correct guidance for the subsequent construction of the photovoltaic power station, avoided waste, and ensured the quality and revenue of the photovoltaic power station.